Over 50 years, Europlex has been active in project development, processing and sale of plastic materials for the wholesale business, industry, life science and other industries. (Thermoplastics, Thermosetting plastics and Elastomers).

Europlex has been assessed and certified as meeting the requirements of IS0 9001:2015 see bottom of this page for the certificates.

Our most used materials are: PEEK, PPSU, PSU, PA6, UHMPE, and POM-C for the medical industrial and automotive markets.

Under processing, we understand:

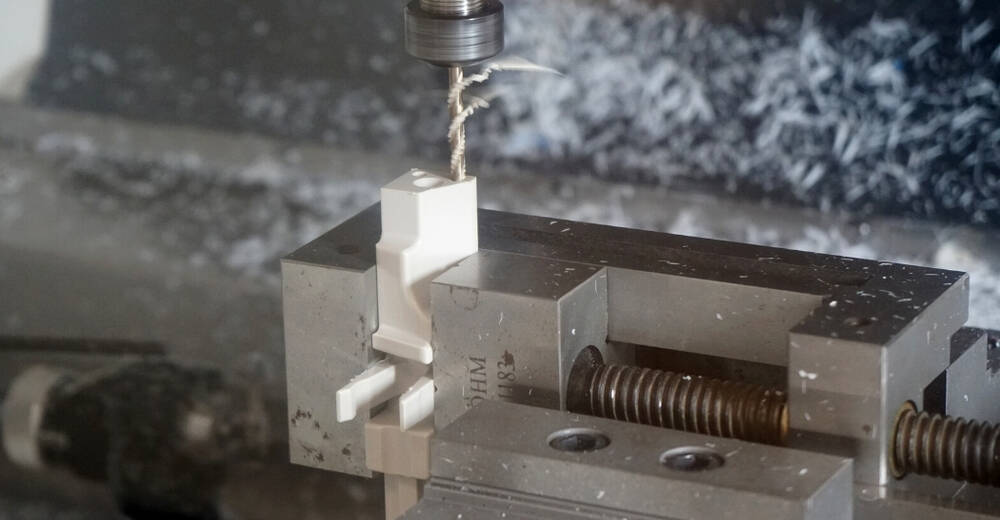

CNC Milling is a machining process that uses a cutting tool to remove material from a workpiece. It is a process by which different shapes and elements can be created on a workpiece by cutting away excess material. In milling, the workpiece is held in a stationary position and the cutting tool is moved around it to give it shape. Milling is used in a wide range of industries, including aerospace, automotive, medical and many more.

CNC turning is a manufacturing process in which a cutting tool is used to remove material from a rotating cylindrical workpiece to achieve a desired shape or finish. CNC turning is used to make parts such as shafts, spindles, bushings and other items for a wide range of industries, including automotive, aerospace and medical.

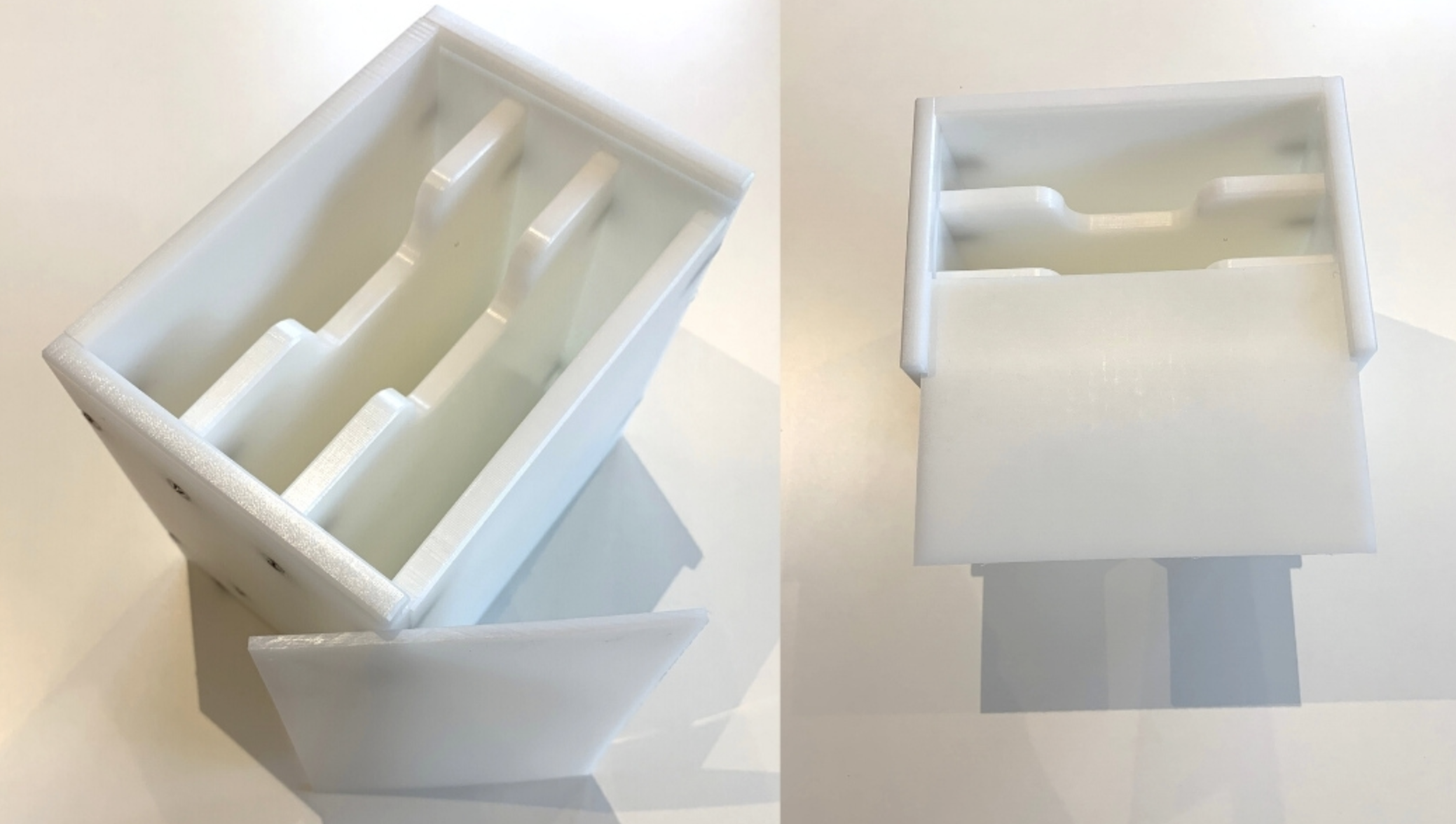

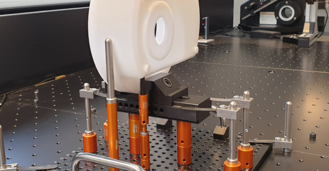

Injection molding is a manufacturing process to make parts from both thermoplastic and a thermoset plastic. It involves melting the material, injecting the material into a mold cavity, and then cooling the part. The process is extremely versatile, allowing parts of different size, shape and complexity to be produced. Our white paper explains this in detail how it works.

Thermoforming is a manufacturing process in which a plastic sheet is heated to a certain temperature, then inserted into a mold in a specific shape and vacuum drawn to produce a usable product. Thermoforming is commonly used to convert plastic into a specific shape. Thermoforming is commonly used to make parts, such as food and beverage containers, medical trays and automotive parts.

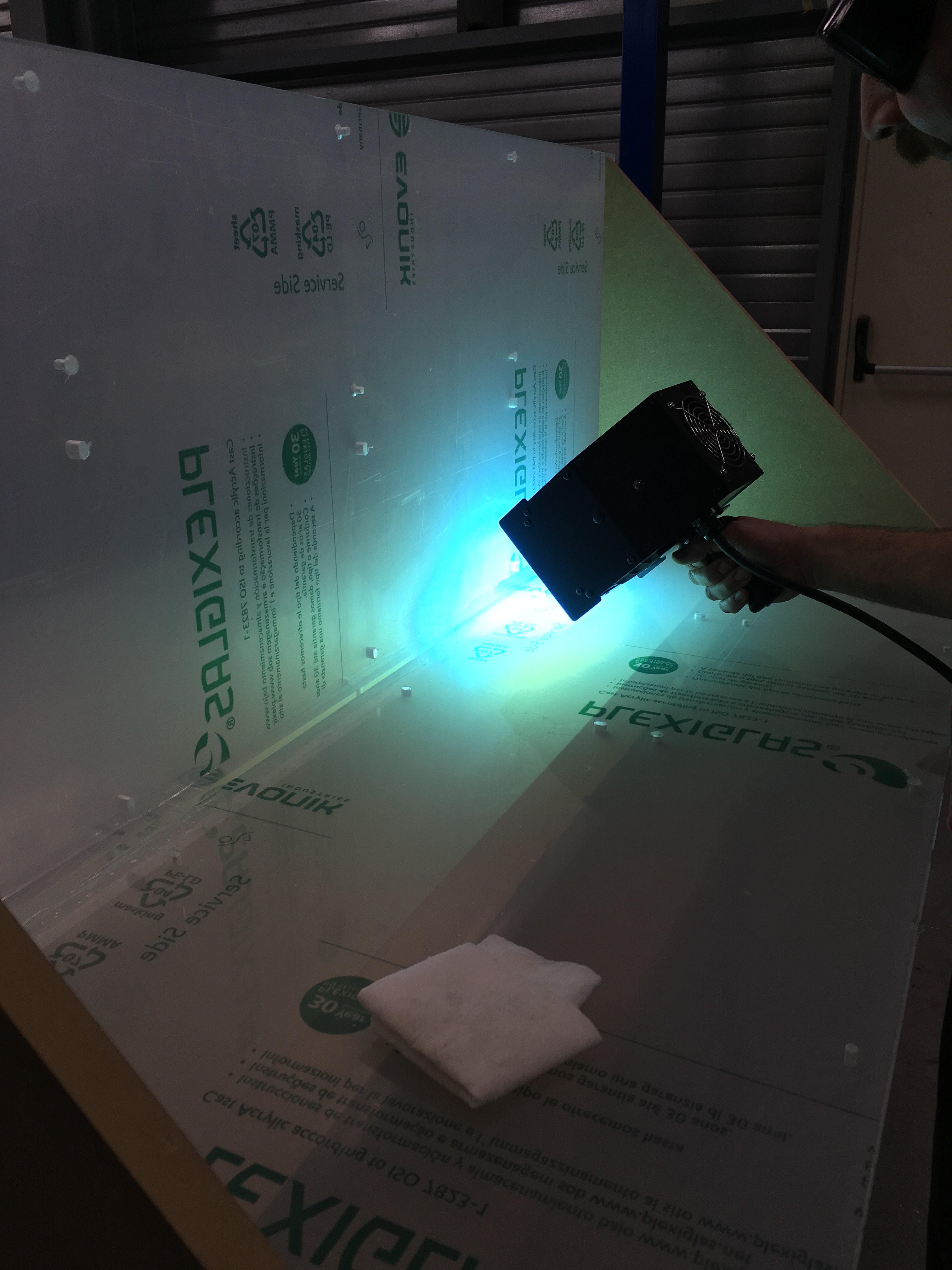

Laser cutting is a technique for cutting materials with a focused laser beam. The laser beam is focused on the material, which then melts, leaving an edge with a high-quality surface finish. (transparent finish in PMMA, Plexiglas) Laser cutting is a fast, accurate and cost-effective way to cut materials for many applications.

Printing Screen printing is a printing technique that uses a fine-mesh screen to transfer a design to a substrate. The design is created by printing ink through the screen onto the substrate. This can also be done digitally provided the size and shape allow it. This application is often used for machine covers where the customer requires an instruction or logo on the product.

Bending and gluing Bending is a manufacturing process that uses force to permanently deform a material. It is used to make parts with curved shapes.

Gluing is the joining of materials by means of an adhesive, in PMMA (Plexiglas) for example this is a 2 component adhesive that produces an (almost) invisible bond. These applications are often used in machine hoods or covers, shields, protection covers, etc....

Polishing plastics is to smooth and even out the surface of plastics to produce a glossy, reflective finish. This process can be done by hand with a soft cloth, with an automatic buffing wheel, or with a Diamond polisher. The type of polish and method used depend on the type of plastic being polished and the desired result. Applications include optical elements, transparent protective covers, LED applications, ...

Tempering It is a process used to reduce tensions (stress) in materials, refine their structure and improve their strength. Tempering involves heating the material to a certain temperature and then slowly cooling it.

Assembly of inserts, helicoils and other mechanical elements. Helicoils in plastics are a type of threaded insert used to create a strong, reusable thread in plastic parts. Helicoils are used in a wide range of applications, including automotive, aerospace, medical and industrial applications. They are usually made of brass, stainless steel or other high-strength materials and are inserted into pre-drilled holes in plastic parts. The helicoil insert is then held in place with a special tool and then the part is ready for assembly. Stainless steel screw inserts (SS) in plastics can be assembled in several ways. The most common method is to use a pre-drilled hole in the plastic part and then use a special tapping tool to screw the insert into the plastic material. Alternatively, inserts can be pressed into the plastic part with a press, or they can be ultrasonically welded into the plastic part.

Please feel free to reach out to us contact@europlex.be or by phone +32 675 507 90

Thanks to our strong team, we are able to work in a very flexible way, and are able to realize a fast completion of the product with superior quality.

Quality is our goal, the reason why we only use materials who meet the REACH, ROHS and EU standards.

Apart from our production plants in Belgium, we also have a production plant in Taiwan. This plant is set up to process big production volumes with worldwide applications, and also works around our 3 pillars: Quality – Flexibility – Cost.

More info about 'injection moulding'? Download our whitepaper below.