Since 1967, Europlex has been a leader in the world of plastics. Over the years we have built up vast experience and knowledge of different markets; especially the industry, medical sector, construction, advertising world, and so on.

Our main activity is the processing of all kinds of plastic materials in all its forms. Take a look at our section services.

Our strength is the ability to go from design to prototype and to small or large series. We also offer the possibility to make a customized design for our customers.

Our shop has the latest new tools, machines, and we work with highly trained people. We are able to answer the demands of our customers with high standards and precision.

Feel free to contact us for more information at europlex@europlex.be

At Europlex we take immense pride in delivering exceptional quality in plastic machining services. We understand the critical importance of precision, reliability, and adherence to industry standards. Let us guide you through the key segments that define our unwavering commitment to quality.

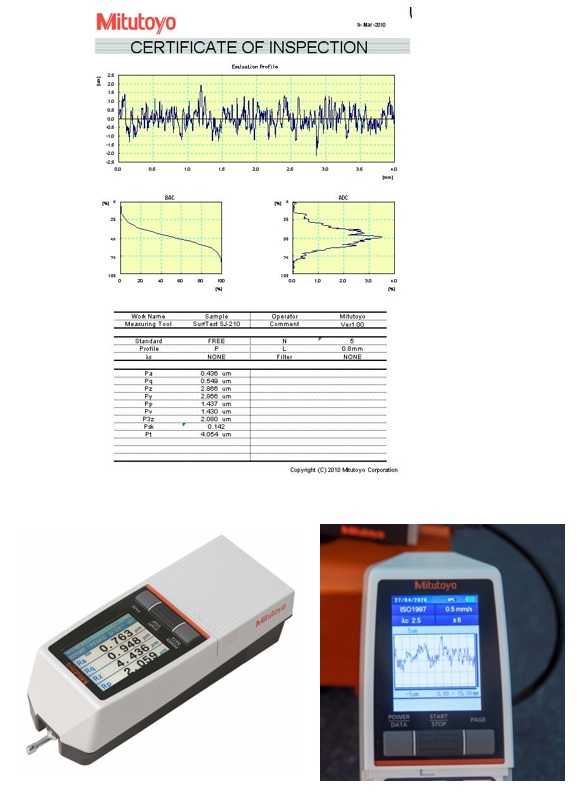

Advanced Quality Tools: Europlex utilizes cutting-edge tools to ensure superior quality outcomes. Our arsenal includes equipment such as a CMM (Coordinate-Measuring Machine) from Mitutoyo, enabling precise dimensional measurements and accurate validation.

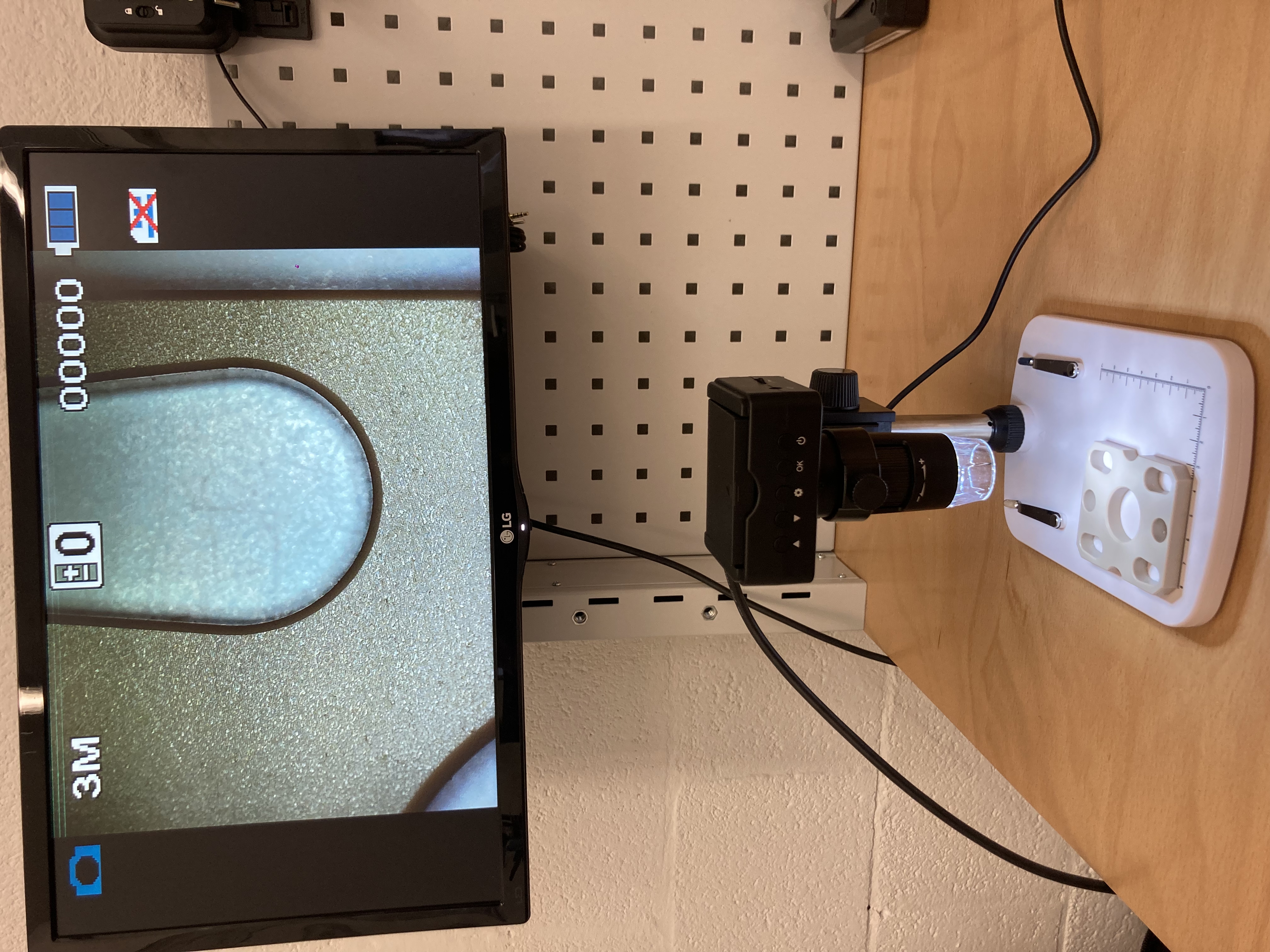

Surface roughness tools (validation of RA, RZ guarantee the desired finish, while microscopes validate intricate small parts with unparalleled precision. We are equipped with go-no go gauges to validate critical dimensions for our esteemed semiconductor customers. Trust Europlex's advanced quality tools for meticulous accuracy and validation.

ISO 9001 Certification: Europlex proudly holds ISO 9001 certification, a testament to our adherence to stringent quality management systems. This internationally recognized certification validates our commitment to consistently meeting and exceeding customer expectations. With Europlex, you can trust that every step of our process is meticulously controlled and monitored to ensure exceptional quality, reliability, and customer satisfaction. Experience the peace of mind that comes with working with an ISO 9001 certified partner.

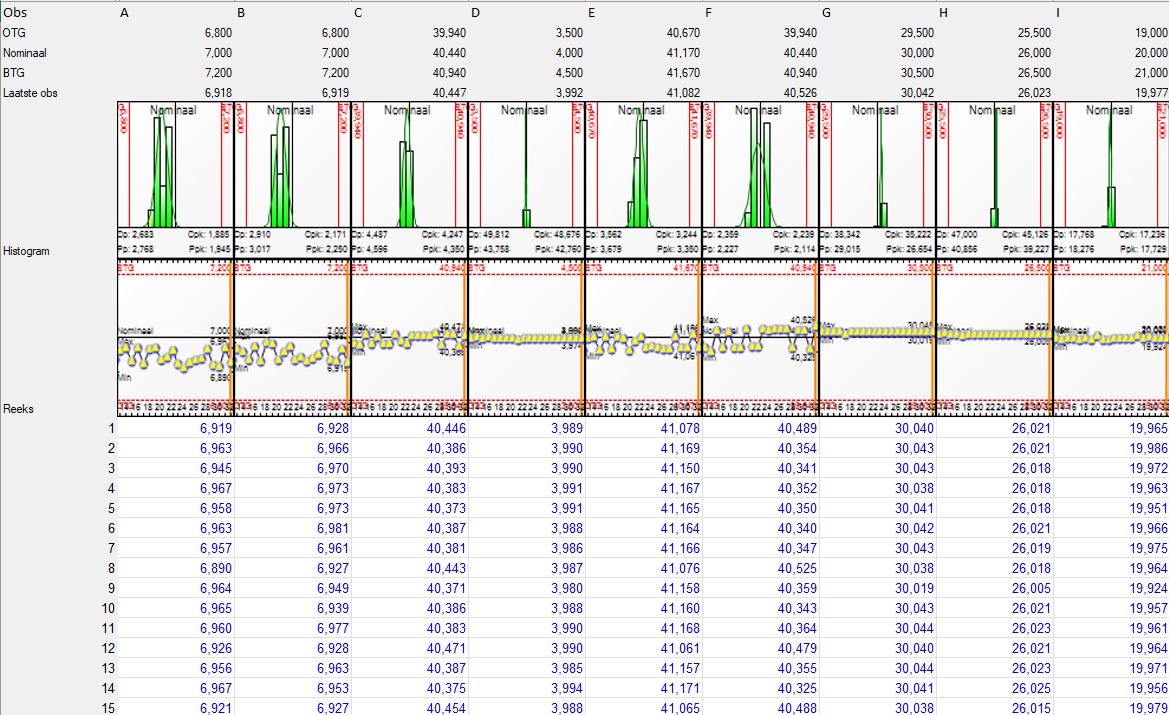

Six Sigma Tools and Lean Practices: Europlex is committed to continuous improvement and efficiency. We employ Six Sigma tools such as CPk, PPk, and Gauge R&R studies to monitor and enhance our manufacturing processes. These tools enable us to maintain exceptional process capability and optimize quality outcomes. As passionate "lean maniacs," we continually seek ways to streamline operations, reduce waste, and maximize value for our customers. We will always review a project from a lean approach that delivers cost-effective solutions without compromising on quality.

Rigorous Inspection Methods: To ensure the highest quality standards, Europlex employs rigorous inspection methods. Our trained professionals conduct comprehensive visual inspections, meticulously evaluating the appearance and integrity of each component. Functional inspection guarantees that our machined parts meet your performance requirements. With Europlex, you can be confident that every product leaving our facility has undergone meticulous scrutiny, surpassing even the most stringent quality benchmarks.

At Europlex, we prioritize meticulous packing and cleaning procedures to ensure the highest level of cleanliness and product integrity. Our commitment to maintaining stringent standards is evident in our use of advanced techniques such as ultrasonic cleaning, IPA 70/30 cleaning, steam cleaning, polishing and cleanroom packing.

Ultrasonic Cleaning: To achieve exceptional cleanliness, we employ ultrasonic cleaning technology. This method utilizes high-frequency sound waves to create microscopic bubbles that gently remove contaminants from the surface of the components. Ultrasonic cleaning ensures thorough and efficient cleaning, even in hard-to-reach areas, resulting in pristine parts ready for use or further processing.

IPA 70/30: To further enhance cleanliness, we utilize Isopropyl Alcohol (IPA) solution with a concentration of 70/30. IPA is a powerful solvent that effectively dissolves oils, greases, and other organic residues. Our precise mixture of IPA and water ensures an optimal cleaning solution, promoting a pristine surface condition for your components.

Cleanroom Packing: To safeguard the cleanliness of your components, we adhere to strict cleanroom packing protocols. Our cleanroom environment minimizes the presence of particles and contaminants, ensuring that the packed components remain pristine throughout the storage and transportation process. Cleanroom packing helps maintain the integrity and quality of your products, providing you with peace of mind. (ISO CLASS 8 standard and ISO6 LAF)

At Europlex, we understand the importance of cleanliness and the impact it has on the performance and reliability of your products. By employing ultrasonic cleaning, utilizing IPA 70/30 and cleanroom packing. We prioritize the integrity and cleanliness of your components at every stage of our process.

Feel free to contact us at contact@europlex.be for more information.

Europlex is the name for all your plastic products or services. We are known for our flexibility and quality, and this at a competitive price.

Building good relationships with our customers and offering high quality services and products are our top priorities. We always act in the best interests of our customers and go above and beyond for them.

At Europlex, we expect nothing but the best of each other and work as a team on your success story.

Europlex was founded in 1976 and has since then gained a firm foothold in the world of plastics. The location in Nivelles, with 2000m² of space, was built in 2000. Over the years, Europlex has built up enormous experience and vast expertise in different markets; in particular the medical sector (life science), industry, the advertising world & retail, and so on. Europlex continues to invest in machinery, lasers and milling machines in order to provide the best service. In 2008 Europlex has expanded with an additional site in Taiwan, which provides many benefits for our customers. Innovation holds no secrets for Europlex, we closely monitor new technologies and we keep on investing in modern equipment such as 5-axis robot machines. In 2015 there was an extra expansion of +/- 600 m² for our location in Nivelles. Since 2018, Europlex has been certified with IS0 9001:2015. You can rely on Europlex, because we are always up-to-date with innovation. In 2019 we bought two new CNC machines and in 2020 we invested in an ERP & CRM software package. In that way we can continue to provide excellent service.