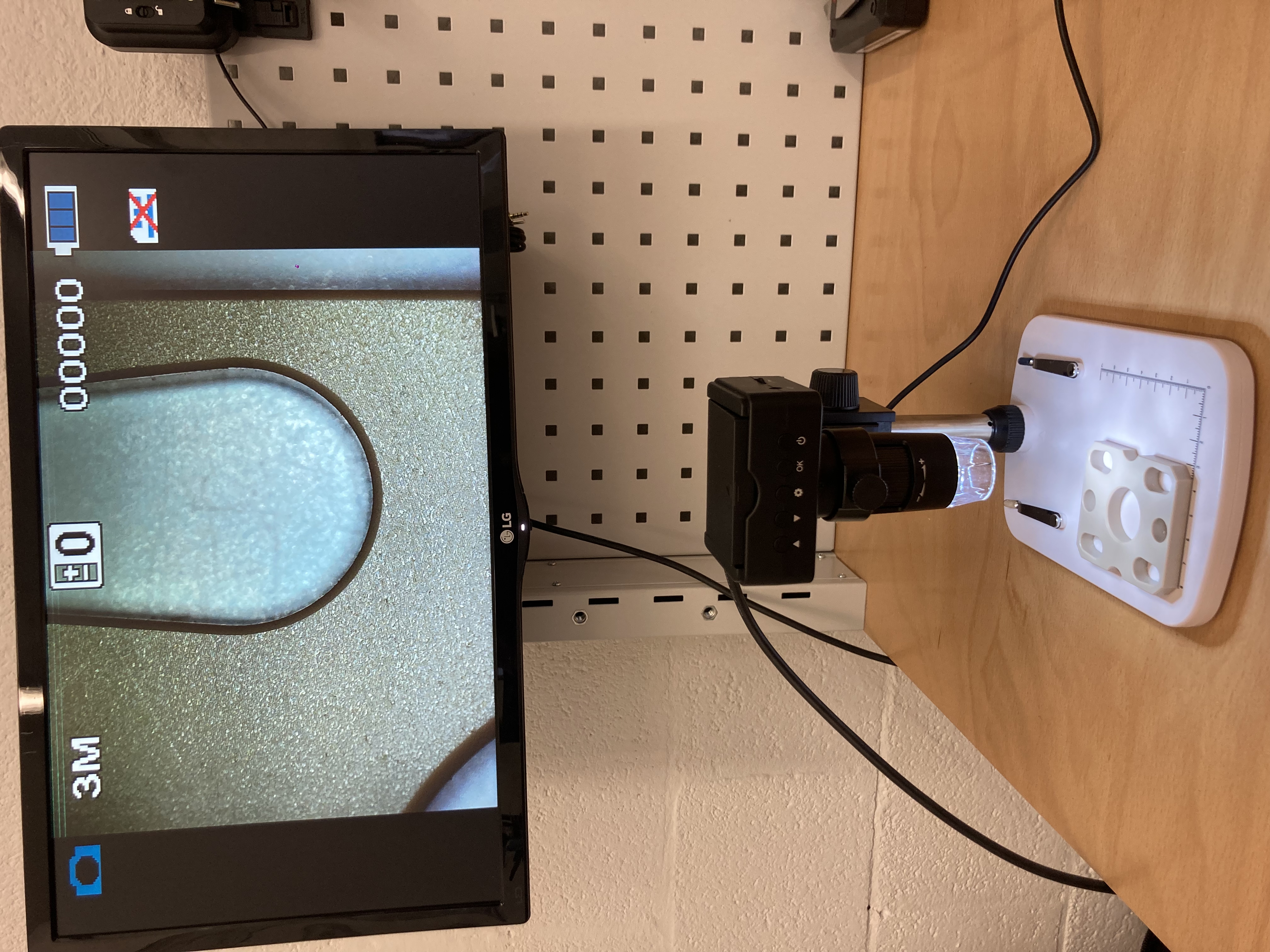

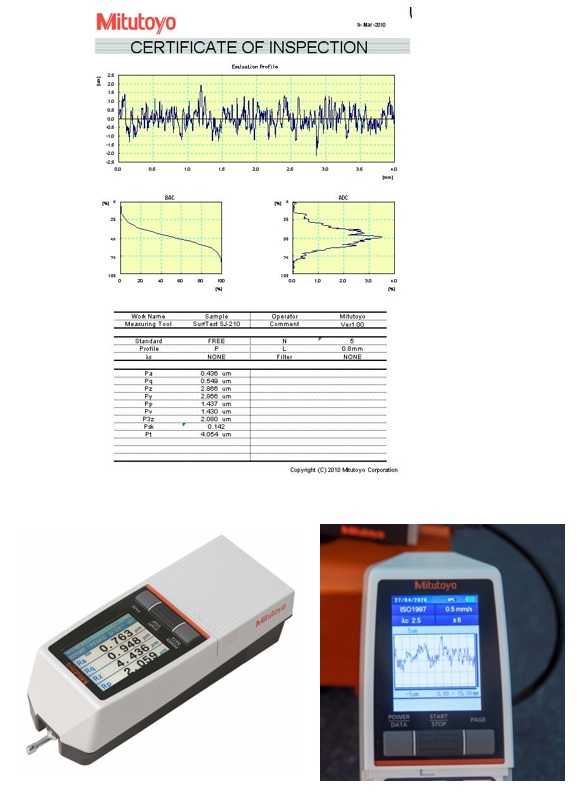

Our machine park is comprised of the latest and most advanced machinery available in the industry. We have invested in a wide range of machinery to ensure that we can offer our customers a comprehensive range of services. Our machinery includes CNC mills, multi-axis lathes, and state-of-the-art machining centers. All our machines are regularly serviced and maintained to ensure optimum performance. We also have a wide range of variuos fabrication equipment, making us a one-stop shop for all your engineering needs.

Please feel free to reach out to us contact@europlex.be or by phone +32 675 507 90

Through this link you can see a laser cutting video : click here

Over the years we have built up vast experience and knowledge of different markets; especially themedical sector, industry and so on.